ITT Goulds Pumps is among the most widely recognized and respected brands in the global pump industry, serving customers in the oil and gas, mining, power generation, chemical, pulp and paper, and general industrial markets. As the only manufacturer to make digital monitoring standard on every process pump, ITT Goulds Pumps still leads the industry in both mechanical pump design and the adoption of smart technologies

ITT Goulds Pump

Model 3181/3186 High Temperature Paper Stock/Process

End suction, top center line discharge, self-venting. Center line mounted for high temperature services. High efficiency enclosed impeller. TaperBore™ seal chamber standard with mechanical seal arrangement. Features i-ALERT condition monitoring as standard.

3181 with ANSI flanges

• Capacities to 13,000 GPM (3000 m 3 /h) • Heads to 410 feet (125 m)

• Temperatures to 508°F (300°C) • Pressures to 360 PSIG (25 bar)

3186 with ISO or JIS flanges

• Capacities to 3,000 m 3 /h (13,000 GPM) • Heads to 125m (410 feet)

• Temperatures to 300°C (508°F) • Pressures to 25 bar (360 PSIG)

Materials: Duplex SS

Model 3180/3185 Paper Stock/Process

All customer requirements were considered in this line of paper stock / process pumps: excellent hydraulic coverage, high efficiency, extreme ease of maintenance, and mechanical reliability.The Model 3185 pump furnished with ISO or JIS flange drilling, metric fasteners, dimensions. Open, enclosed or Shearpeller™ impellers available. Features i-ALERT condition monitoring as standard. Model 3180 standard with ANSI flanges.

3180

• Capacities to 45,000 GPM (10,220 m³/h) • Heads to 410 feet (125 m)

• Temperatures to 446° F (230° C) • Pressures to 232 PSIG (16 bar)

3185 with Metric standards

• Capacities to 26,000 GPM (6,000 m3/h) • Heads to 125 m (410 feet)

• Temperatures to 230°C (446°F) • Pressures to 16 bar (232 PSIG)

Materials: All Iron / 316SS Trim, 316SS, 317SS, CD4MCu

Model 3171 and CV 3171 Vertical Sump and Process

The CV 3171 is a recessed impeller, circular volute type sump pump. Ideal for large solids and shear sensitive fluids. Circular volute minimizes radial loads making this the ideal pump for low flow process applications.

- Capacities to 1,300 GPM (295 m3/h)

- Heads to 230 feet (126 m)

- Temperatures to 450° F (232° C)

- Pit Depths to 20 feet (6 m)

Materials: Cast Iron, Duplex SS, 316SS,

Alloy 20, Hastelloy B and C

The “Veteran” vertical sump and process pump. Thousands of installations – industrial process, sump drainage, corrosive liquids, pollution control, molten sulfur. Rugged, heavy construction. Simple mounting.

- Capacities to 3,180 GPM (722 m³/h)

- Heads to 344 feet (95 m)

- Temperatures to 450° F (232° C)

- Pit Depths to 20 feet (6 m)

Materials: Cast Iron, Bronze-fitted, Carbon Steel, 316SS, Alloy 20,

Model 3175 Paper Stock/Process

For the toughest services. Thousands of installations handle stock, solids, fibrous/stringy materials, abrasive slurries, and corrosives.Dynamic seal option eliminates mechanical seal problems. Features i-ALERT condition monitoring as standard.

- Capacities to 28,000 GPM (6,360 m³/h)

- Heads to 350 feet (107 m)

- Temperatures to 450°F (232° C)

- Pressures to 285 PSIG (20 bar)

Materials: All Iron / 316SS Trim, 316SS, 317SS,

CD4MCuN

ANSI Process Pumps

Model 3196 ANSI Process

This is the original ANSI pump that has become the standard of the industry. Over 1,000,000 installations attest to the remarkable performance of the 3196. Available with a wide range of features for handling difficult applications. i-FRAMETM power ends maximize reliability and MTBF (Mean Time Between Failure).

- Capacities to 7,000 GPM (1,364 m³/h)

- Heads to 730 feet (223 m)

- Temperatures to 700° F (371° C)

- Pressures to 375 PSIG (26 bar)

Materials: Ductile Iron, 316SS, CD4MCu, Alloy 20, Monel, Nickel, Hastelloy B and C, Titanium

Model HT 3196 ANSI High Temperature Process Pump

Center line mounted in a heavy duty fabricated steel casing support, the Model HT 3196 minimizes shaft misalignment and piping strain associated with elevated temperatures up to 700° F. As a member of the ANSI pump family the HT3196 features Goulds Pumps’ premier i-FRAMETM power end, multiple seal chamber options including the TaperBore PLUS, and a wide variety of rigid and rugged mounting systems.

- Capacities to 4,500 GPM (1,023 m³/h)

- Heads to 925 feet (282 m)

- Temperatures to 700° F (371° C)

- Pressures to 450 PSIG (31 bar)

Materials: Carbon Steel, 316SS, CD4MCu,

Alloy 20, Hastelloy C

Model LF 3196 Low Flow ANSI Process

Designed specifically to provide superior performance for low flow services. Features a concentric (circular volute) casing and open radial vane impeller to eliminate hydraulic and mechanical problems at low flows. Includes i-FRAME power ends.

- Capacities to 220 GPM (50 m³/h)

- Heads to 925 feet (282 m)

- Temperatures to 700° F (371° C)

- Pressures to 450 PSIG (31 bar)

Materials: Ductile Iron, 316SS, CD4MCu,

Alloy 20, Hastelloy B and C

Model CV 3196 Non-Clog ANSI Process

Perfect solution for handling bulky, fibrous, or shear-sensitive liquids. Recessed impeller design provides non-clog pumping with minimum solids degradation. Capability to handle liquids containing 10 to 20 percent air/gas. i-FRAMETM power ends.

- Capacities to 2,700 GPM (610 m³/h)

- Heads to 440 feet (134 m)

- Temperatures to 500° F (260° C)

- Pressures to 285 PSIG (20 bar)

Materials: Ductile Iron, CD4MCu,

Hastelloy B and C, Alloy 20

Model 3996 In-Line ANSI Process

For corrosives, abrasives and high temperature. Fully open impeller, back pull-out design, heavy duty construction. Field alignment not required.

- Capacities to 1,400 GPM (318 m³/h)

- Heads to 700 feet (213 m)

- Temperatures to 500° F (260° C)

- Pressures to 375 PSIG (26 bar)

Materials: Ductile Iron, 316SS, Monel, Alloy 20, Nickel,

Hastelloy B and C, CD4MCu, Titanium

Sealless Process Pumps

Model 3296 EZMAG Magnetic Drive ANSI Process

Robust, simple sealless design ideal for difficult liquids such as corrosives, pollutants, ultra-pure liquids and toxics. Meets ANSI dimensional specifications. Features a bearing cartridge for ease of maintenance and improved reliability.Capacities up to 700 GPM

(159 m³/h)

- Heads to 700 feet (213 m)

- Temperatures to 535° F (280° C)

- Pressures to 275 PSIG (19 bar)

Materials: 316SS, others upon request

Model 3299 Magnetic Drive ANSI Lined

Designed to handle moderate to severe corrosives with or without solids. Sealless design provides effective alternative to pumps with mechanical seal problems. Thick linings for extended pump life.

- Capacities to 425 GPM (95 m³/hr)

- Heads to 490 feet (149 m)

- Temperatures to 360° F (180° C)

- Pressures to 275 PSIG (19 bar)

Lining Material: PFA

Model 3298 Magnetic Drive ANSI Lined

Designed to handle moderate to severe corrosives with or without solids. Sealless design provides effective alternative to pumps with mechanical seal problems. Thick linings for extended pump life.

- Capacities to 1,200 GPM (270 m³/hr)

- Heads to 350 feet (162 m)

- Temperatures to 250° F (121°C)

- Pressures to 225 PSIG (16 bar)

Lining Material: Tefzel® (ETFE)

Sealed Lined & Non-Metallic

Model 3198 PFA Process ANSI Lined

Virgin PFA Teflon® for handling a wide range of severe corrosive liquids, trace contaminants, and mixtures. The 3198 features ANSI B73.1 design, and i-ALERT power ends. Teflon® molded in place by high pressure technique and mechanically locked.

- Capacities to 800 GPM (182 m³/h)

- Heads to 450 feet (137 m)

- Temperatures to 300° F (149° C)

- Pressures to 225 PSIG (16 bar)

Material: PFA Teflon®

Model NM3196 FRP ANSI Process

The Fiberglass reinforced Vinyl Ester construction provides excellent corrosion resistance in many aggressive acidic and caustic services. The random glass orientation and generous ribbing provides flange load ratings equal to a metal pump of the same size. The true volute design provides the highest efficiencies in the industry for FRP ANSI pumps.

- Capacities to 1,400 GPM (318 m³/h)

- Heads to 500 feet (152 m)

- Temperatures to 200° F (93° C)

- Pressures to 220 PSIG (15 bar)

Materials: Glass reinforced Vinyl Ester, other resins available upon request

ISO Process Pump

Model IC ISO Process

This series is designed in accordance with ISO 5199 and ISO 2858, making it ideal for worldwide chemical or industrial process applications. IC pumps are fitted with a patented seal chamber design called the Cyclone seal chamber, which has been proven to provide the optimum sealing environment for extended mechanical seal life. Optional inducer reduces NPSHr.

- Capacities to 1,980 GPM (450 m3/h)

- Heads to 525 feet (160 m)

- Temperature ranges from -40° F to 530˚ F (-40° C to 280° C)

- Pressures to 360 PSIG (25 bar)

Materials: Ductile Iron, Carbon Steel, 316SS, Duplex SS, Alloy 20, Hastelloy C, Titanium

API 610 Process Pumps

7200CB (BB5) Barrel Multistage Pumps

11th edition API compliant, severe service, barrel pumps, in-line diffuser style. For high temperatures, pressures and low specific gravities.

- Capacity: 4,000 GPM (910 m³/h)

- Head: 9,000 feet (2,740 m)

- Temperature: 800˚F (425˚C)

- Pressure: 4,000 PSIG (275 bar)

Materials: All API materials, custom materials available

Model 3700 & 3710 API 610 (OH2) Overhung Process

High temperature and high pressure process pumps designed to fully meet the requirements of API 610. Center line support for high temperature stability, maximum rigidity. Features tangential discharge for maximum hydraulic efficiency. Available in top suction design (Model 3710).

- Capacities to 8,500 GPM (1930 m³/h)

- Heads to 1,200 feet (360 m)

- Temperatures to 800° F (425° C)

- Pressures from full vacuum to 870 PSIG (60 bar)

Materials: All API materials, custom materials available

Model API 3171 (VS4) API 610 Vertical Sump and Process

For all refinery services requiring tank mount or sump duties. Fully compliant with 10th and 11th editions ISO 1370/API 610.

- Capacities to 3,180 GPM (722 m³/h)

- Heads to 525 feet (160 m)

- Temperatures to 450° F (232° C)

- Pit depths to 20 feet (6 m)

Materials: Carbon Steel, 316SS, 12% Chrome Fitted, Duplex SS

Model 3910 API 610 (OH3) Vertical In-Line with Bearing Frame

High pressure, high temperature services meets API 610 requirements. Back pull-out for ease of maintenance. Bearing frame carries pump loads.

- Capacities to 6,000 GPM (1,360 m³/h)

- Heads to 750 feet (230 m)

- Temperatures to 650°F (340° C)

- Pressures to 600 PSIG (42 bar)

Materials: All API materials, custom materials available

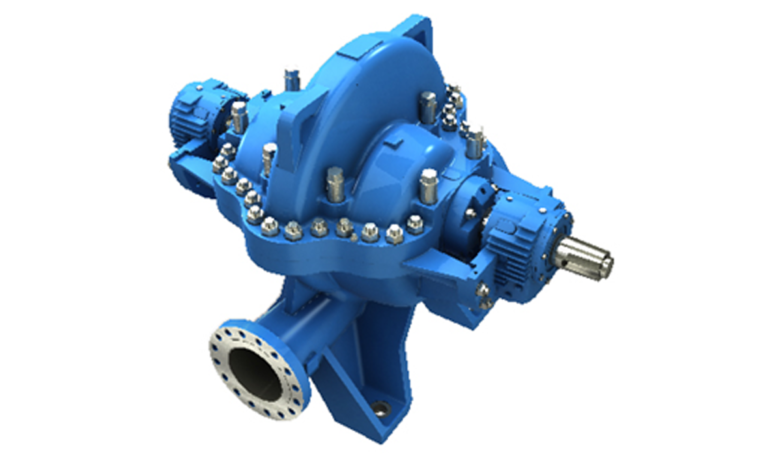

Models 3620 and 3640 API 610 (BB2) Single and Two-Stage Between Bearings

Between bearings, radially split process pumps designed for smooth, reliable operation. Fully meets requirements of API 610.

- Capacities to 20,000 GPM (4,540 m³/h)

- Heads to 1,500 feet (455 m)

- Temperatures to 850° F (455° C)

- Pressures to 1,000 PSIG (70 bar)

Materials: All API materials, custom materials available

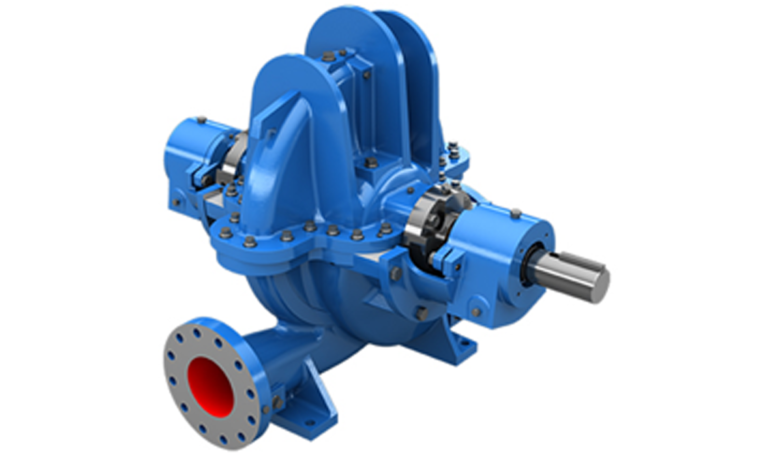

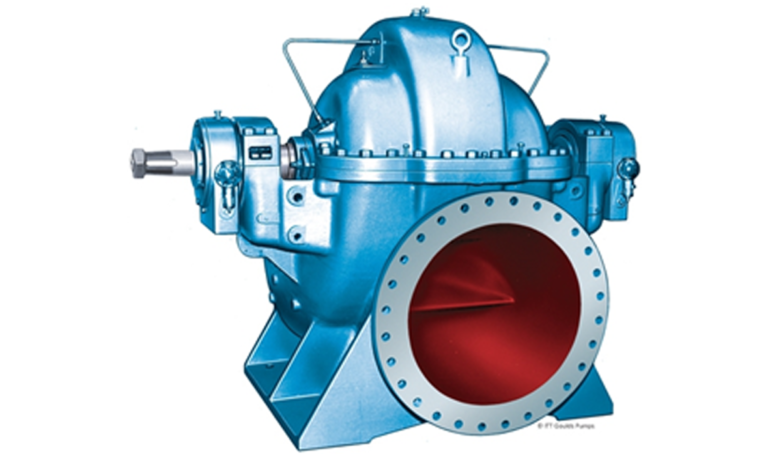

Model 3610 API 610 (BB1) Horizontal Split Case, Double Suction

Designed for a wide range of industrial, municipal and marine services.

- Capacities to 50,000 GPM (11,355 m³/hr)

- Heads to 700 feet (215 m)

- Temperatures to 300° F (150° C)

- Pressures to 300 PSIG (21 bar)

Materials: All API materials, custom materials available

Model 3600 API 610 (BB3) Heavy Duty Multistage

Advanced design with proven operating history. Axially split, with many enhanced features that make it an extremely reliable, high performance pump well-suited to a wide range of services.

- Capacities to 8,500 GPM (1,930 m³/hr)

- Heads to 9,000 feet (2,740 m)

- Temperatures to 400° F (205° C)

- Pressures to 4,000 PSIG (275 bar)

Materials: All API materials, custom materials available

Multistage / Axial Flow / Double Suction

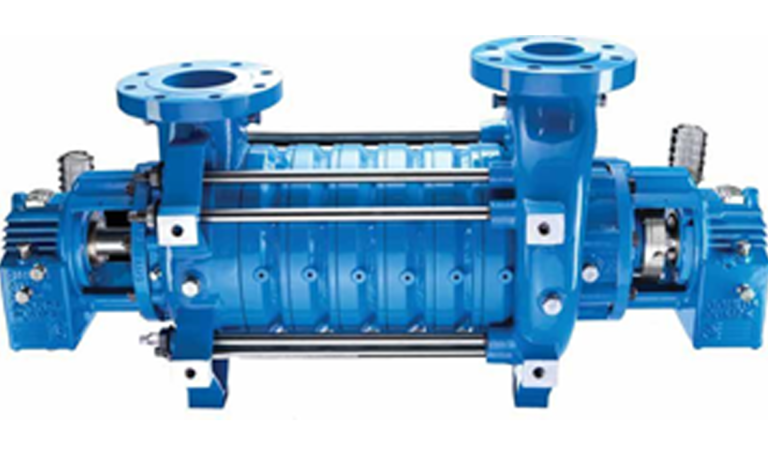

Model 3311 High Pressure Multistage

Radially split, segmented multistage pump; a proven state-of-the-art design for the most demanding high pressure services. Many special features for application flexibility. Ideal for co-generation, boiler feed, reverse osmosis, booster, water and oil.

- Capacities to 1,100 GPM (250 m³/h)

- Heads to 5,250 feet (1,600 m)

- Temperatures to 356° F (180° C)

- Pressures to 2,320 PSIG (160 bar)

Materials: 12% Chrome / Cast Iron and 12% Chrome / 316ss

Model 3316 Two-Stage Splitcase

Horizontal split case pumps are ideally suited for boiler feed, mine dewatering and other services requiring moderately high heads with a wide range of operating conditions.

- Capacities up to 3,000 GPM (681 m³/h)

- Heads to 1,000 feet (305 m)

- Temperatures to 350° F (177° C)

- Pressures to 550 PSIG (38 bar)

Materials: Bronze-fitted, Cast Iron, Bronze, 316SS

Model 3393 High Pressure Multistage Ring Section Pump

Radially split, segmented casing, multistage pump designed with modular interstage components. Its multiple suction nozzle and discharge nozzle orientations allow adaptation to multiple piping installations. Multiple hydraulics for each pump size optimize efficiency across a vast range of applications. These pumps are particularly well suited for reverse osmosis and boiler feed applications. Shower services, booster service and other high pressure services are applications where it may be applied.

- Capacities to 3,000 GPM (680 m³/h)

- Heads to 3,300 feet (1,000 m)

- Temperatures to 400° F (204° C)

- Pressures to 1,650 PSIG (114 bar)

Materials: Carbon Steel, Carbon Steel/12% Chrome Fitted, 12% Chrome, Duplex and Super Duplex

Model 3355 Multistage

Multistage ring section pump designed for high pressure services including: reverse osmosis, shower service, boiler feed and much more.

- Capacities to 1,500 USGPM (340 m³/h)

- Heads to 1,640 feet (500 m)

- Max speed to 3,600 rpm (3,600 min-1)

- Discharge from 1½” to 5″

- Temperatures to 280° F (140° C)

- Pressures to 800 PSIG (55 bar)

Materials: Cast Iron, Stainless Steel, Stainless Fitted

Model 3935 Centrifugal Diffuser Multistage

Centrifugal diffuser type multistage pumps well suited for boiler feed, reverse osmosis, petrochemical and hydrocarbon services.

- Capacities to 125 GPM (28 m³/h)

- Heads to 2,600 feet (792 m)

- Temperatures to 400° F (204° C)

- Pressures to 1,500 PSIG (103 bar)

Material: Carbon Steel

3400 Series Horizontal Split Case, Double Suction

Goulds 3410 Small Capacity

- Capacities to 8,000 GPM (1,817 m3/h)

- Heads to 570 feet (174 m)

- Temperatures to 350° F (177° C)

- Pressures to 250 PSIG (1,724 kPa)

Goulds Model 3409Medium Capacity

Designed for a wide range of industrial, municipal and marine services.

- Capacities to 12,000 GPM (2,725 m3/h)

- Heads to 850 feet (259 m)

- Temperatures to 250°F (120°C)

- Working Pressures to 400 PSIG (2758 kPa)

Materials: Cast Iron / Bronze, All Iron, All Bronze, Cast Iron / Stainless Steel, All Stainless Steel (1724 kPa)

Goulds Model 3420 Large Capacity

Designed for a wide range of industrial, municipal and marine services.

- Capacities to 65,000 GPM (14,762 m3/h)

- Heads to 400 feet (122 m)

- Temperatures to 275°F (135°C)

- Working Pressures to 200 PSIG (1379 kPa)

Materials: Cast Iron / Bronze, All Iron, All Bronze, Cast Iron / Stainless Steel, All Stainless Steel (1724 kPa)

Model Axial Flow® Axial Flow

For continuous circulation of corrosive/abrasive solutions, slurries, and process wastes. Fabricated elbow or cast elbow designs available. Most suitable for low head, high capacity pumping.

- Capacities to 300,000 GPM (68,000m3/h)

- Heads to 30 feet (9.2 m)

- Temperatures to 350° F (176° C)

- Available in cast iron, austenitic stainless steels, duplex alloys, nickel, nickel-chrome alloys, nickel-chromemoly alloys, titanium and other alloys as required for the service

- Available in 6 – 66 inch sizes (larger sizes on application)

Materials: Cast Iron, 304SS, 316SS, CD4MCu, Nickel, Monel, Alloy 20, UHB-904L, Titanium, Hastelloy, Sanicro 28

Vertical Mixed & Axial Flow

Models WCAX-GP, YDD-GP, WCA-GP, WCB-GP, WCC-GP, WCE-GP, WCL-GP, WMCC-GP, WMCE-GP, WCAG-GP

Custom designed for maximum reliability and high efficiency.

VERTICAL PUMPS

Model VIC Vertical Can-Type

A wide range of hydraulic conditions allows meeting requirements of virtually every pumping service. Designed to meet custom specifications of the user. Model VIC can-type turbine meets API 610 specifications.

- Capacities to 70,000 GPM (15,900 m3/Hr)

- Heads to 3,500 feet (1,067 m)

- Pressures to 2,500 psi (176 kg/cm2 )

- Bowl sizes from 6” to 55” (152.4 mm to 1,400 mm)

- Temperatures to 500° F (260°C)

- Horsepower to 5,000 HP (3730 KW)

Materials: Any Machinable Alloy

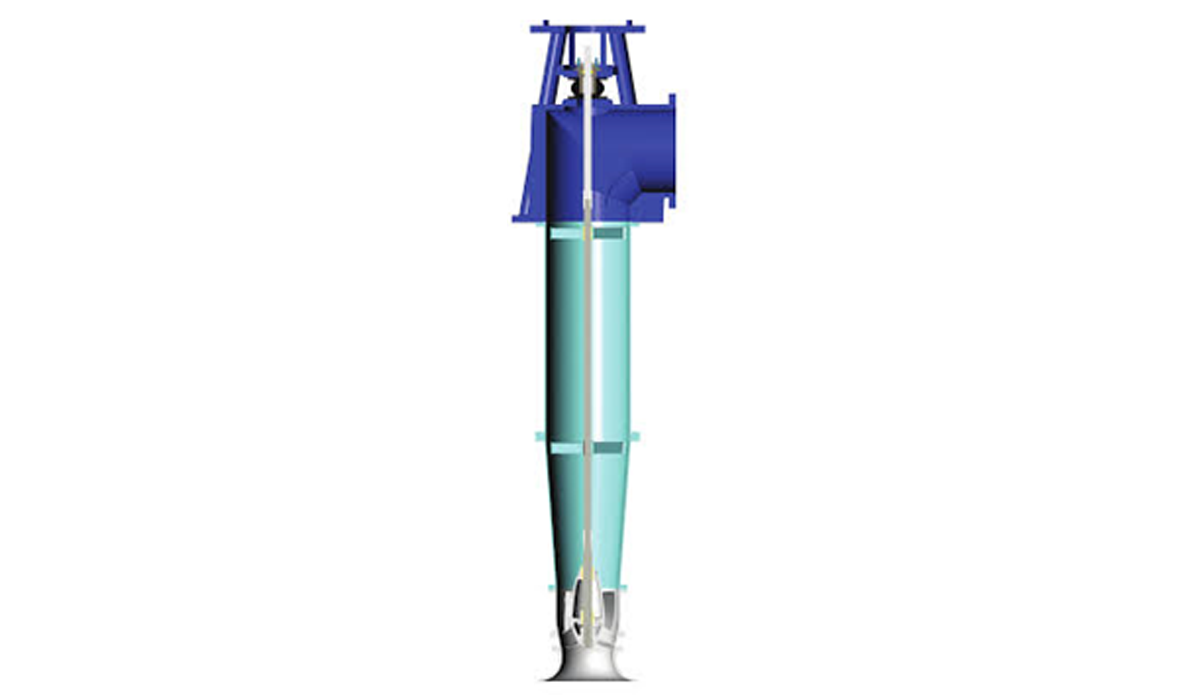

Model VIT Vertical Pumps

A wide range of hydraulic conditions allows meeting requirements of virtually every pumping service. Designed to meet custom specifications of the user. Model VIT can-type turbine meets API-610

specifications.

- Capacities to 70,000 GPM (15,900 m3/Hr)

- Heads to 3,500 feet (1,067 m)

- Pressures to 2,500 psi (176 kg/cm2)

- Bowl sizes from 6” to 55” (152.4 mm to 1,400 mm)

- Temperatures to 500° F (260°C)

- Horsepower to 5,000 HP (3,730 KW)

Materials: Any Machinable Alloy

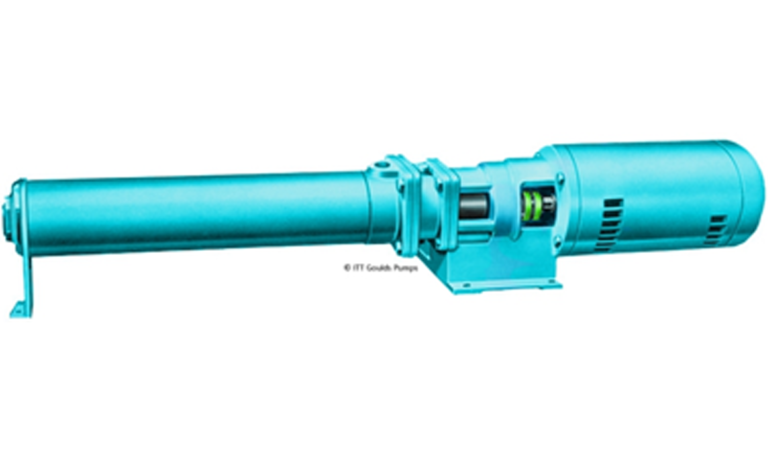

Model VIS Vertical Submersible

For deep settings or where use of line-shaft pumps is impractical. For irrigation, service water, deep well supply, offshore and mine de-watering.

- Capacities to 70,000 GPM (15,900 m3/hr)

- Heads to 3,500 feet (1,067m)

- Pressures to 2,500 psi (176 kg/cm2)

- Bowl sizes from 6” to 55” (152.4 mm to 1,400 mm)

Materials: Any Machinable Alloy