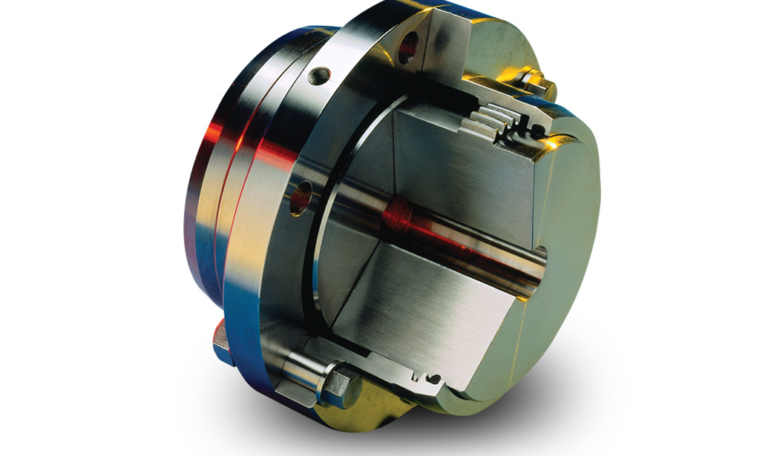

Flex-A-Seal a leading manufacturer of custom engineered mechanical seals, welded metal bellows and the world’s only patented split cartridge mechanical seal.

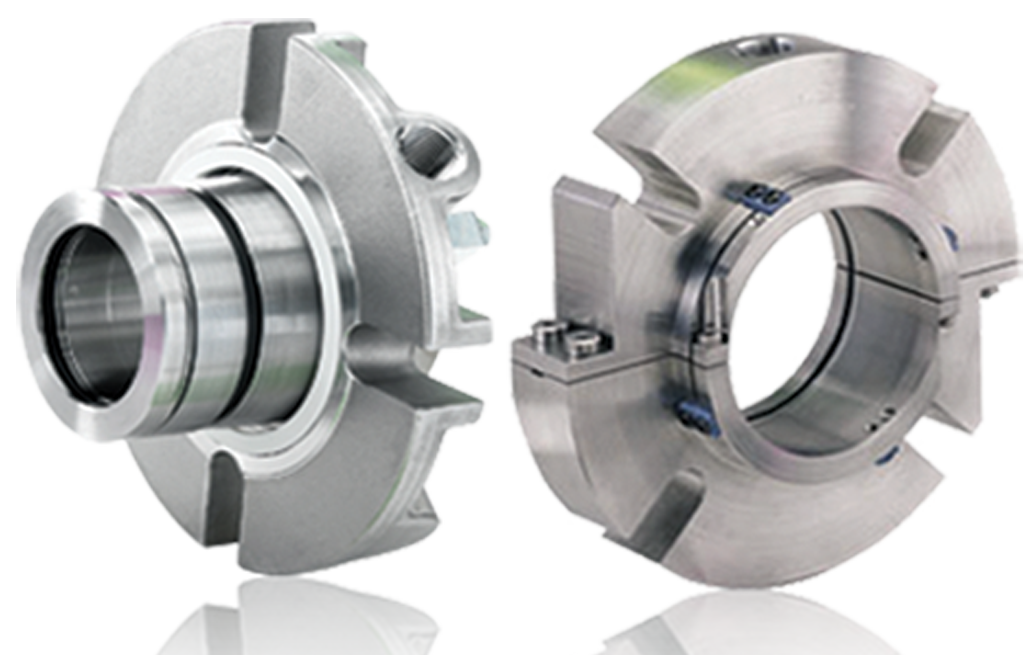

WELDED METAL BELLOWS

SINGLE CARTIDGE MULTIPLE SEAL

HEAVY DUTY SLURRY SEAL

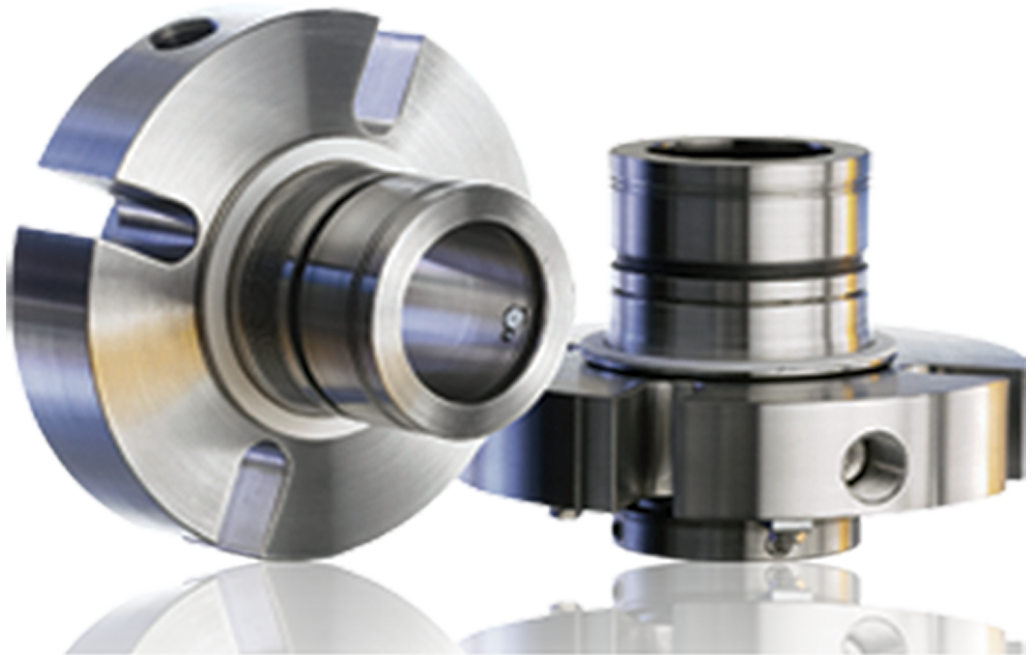

SINGLE CARTRIDGE

DOUBLE CARTRIDGE SEAL

Bibby Turboflex

G-Flex – Grid Couplings

Product Feature

- Torque range up to 1,500,000 in.lb. (169 kNm)

- Easy to assemble/replace

- Part-for-part interchangeable with industry standard tapered grid coupling designs

- Coupling sizes 1020 through 1140 in-stock in a range of standard bore sizes

- Shot-peened tapered grid flex element for long life

Pin & Bush Couplings

Product Feature

- Up to 96 KNm; 548 in.lbs.

- Vertical or horizontal operation

- 80 or 90 shore hardness close fitting flexible elements

- Steel or cast iron hubs

- Brake drum or disc available as well as special designs

- Simple Assembly

- Parallel or Taper bore options

Series III – Gear Couplings

Product Feature

- Up to 147 kNm; 1,300,000 in.lb.

- Fully-crowned gear teeth provide maximum contact at the strongest part of the tooth.

- Models available for use on vertical and/or horizontal shafts

- Bore capacity up to 645 mm

- High torque to weight ratio

- Half per half interchangeability with other gear couplings manufactured to AGMA standards

- Single, Double and Rigid designs available

- ±3/4° angular misalignment capacity per gear mesh

- Torque ratings at full misalignment-in excess of normal requirements for average applications

- Accurately machined medium carbon steel hubs and Sleeves

- Positive-type 0-ring seals keep lubricant in and contaminants out

- Seals enshrouded to prevent damage

Turboflex High Speed Couplings

Turboflex High Speed Couplings is capable of transmitting high torques at high speeds whilst accepting considerable levels of angular, radial, and axial misalignment.

Standard units are compliant with API 671 and ATEX Certified

Turboflex High Performance Couplings

These torsionally stiff, light weight couplings are capable of transmitting high torques at high speeds while tolerating significant levels of angular, radial, and axial misalignment. Easy to install and suited for adverse conditions, it requires no lubrication and features a high torque to weight ratio.

Turboflex Plus High Performance Disc Couplings

Two leading international flexible coupling manufacturers, Ameridrives® International and Bibby Turboflex offers a new series of high performance disc couplings designed that meet the stringent requirements of today’s turbomachinery market.

Torsiflex Pump Couplings

Torsiflex couplings are specifically designed for the process pump and general industrial markets. Torsiflex is an all-metal disc coupling that needs no lubrication and incorporates a plug-in feature to allow installation and removal without disturbing the pump alignment.

Over 65 years of real-world experience with side entry mixer application in the petroleum industry.

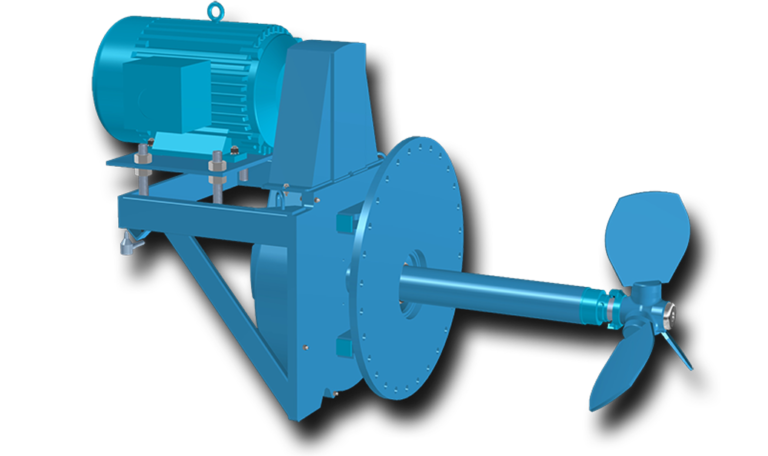

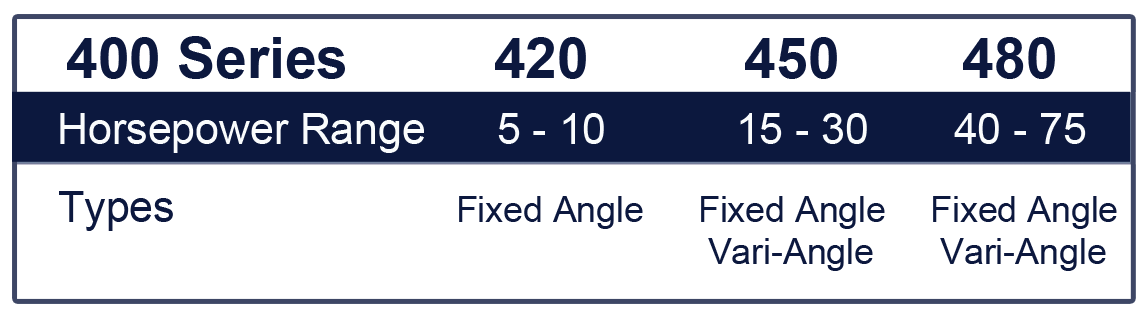

400 Series Belt Drive Side-Entry Mixer

for Product Blending, Sediment Control & Tank Cleaning Applications

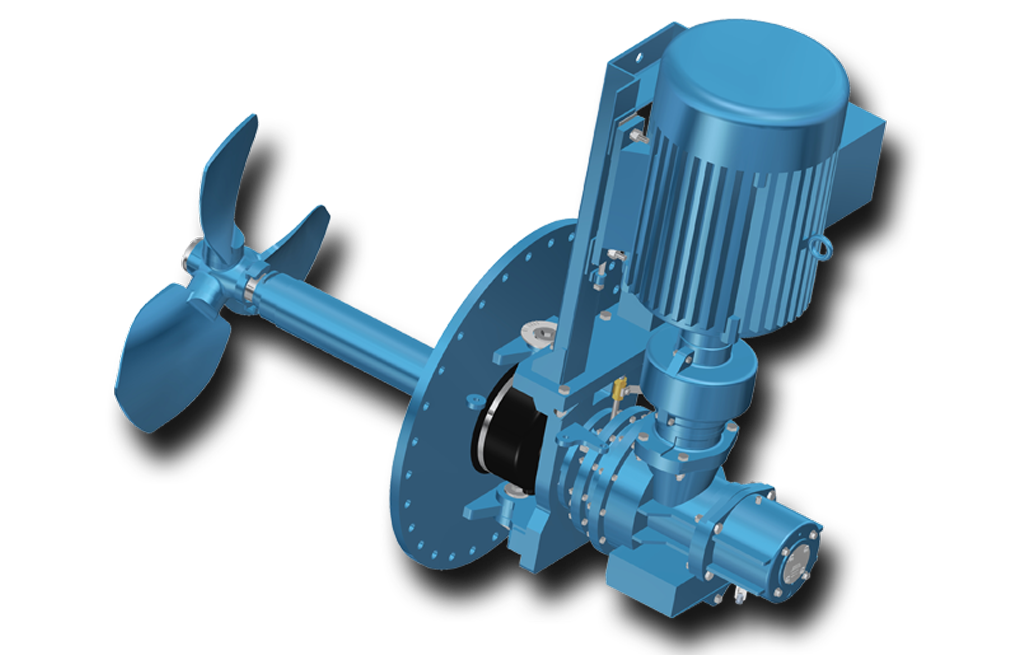

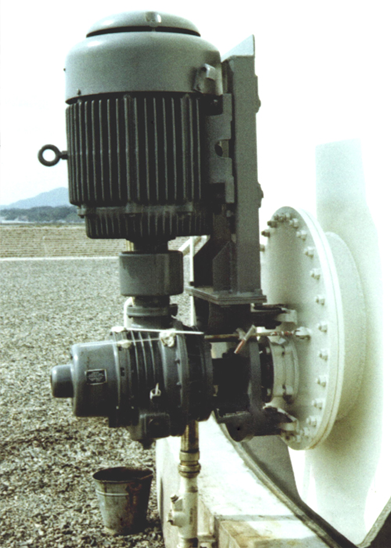

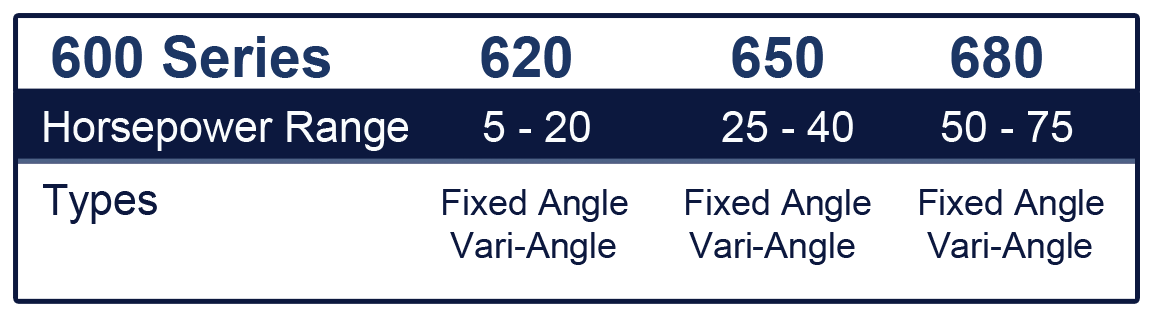

600 Series Gear Drive Side-Entry Mixer

for Petroleum Applications

PROTEGO® offers a comprehensive line of flame arresters, valves, and tank accessories that are tailored to meet market demands.

The products are installed for a wide range of applications:

- * In tank farms for flammable liquids in industrial and military applications

- * In chemical and pharmaceutical processing facilities

- * In vapour combustion plants

- * In biogas, landfill gas and wastewater treatment plants

- * In shipbuilding; on oil platforms, and in loading and unloading facilities.

FLAMEARRESTER

End-of-Line Flamearrester

Nominal Size: 15 to 800 mm (1/2” to 32”)

Detonation Flamearrester

Nominal Size: 15 to 800 mm (1/2” to 32”)

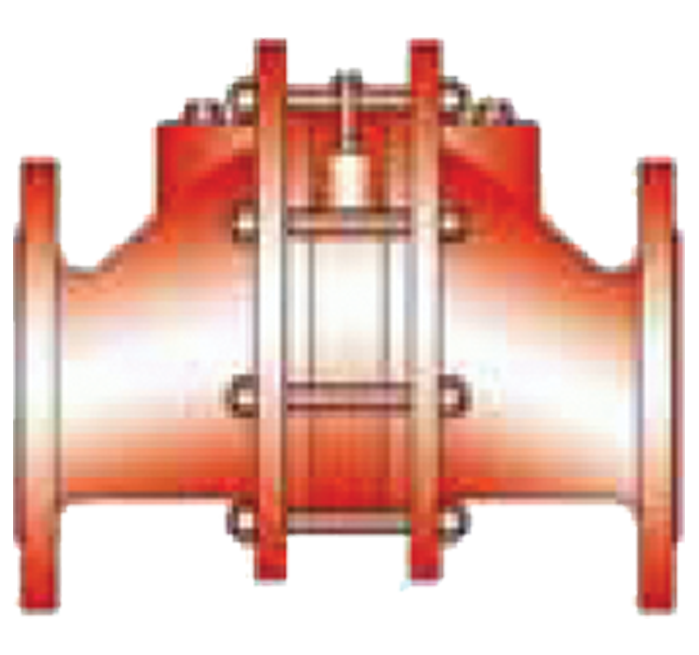

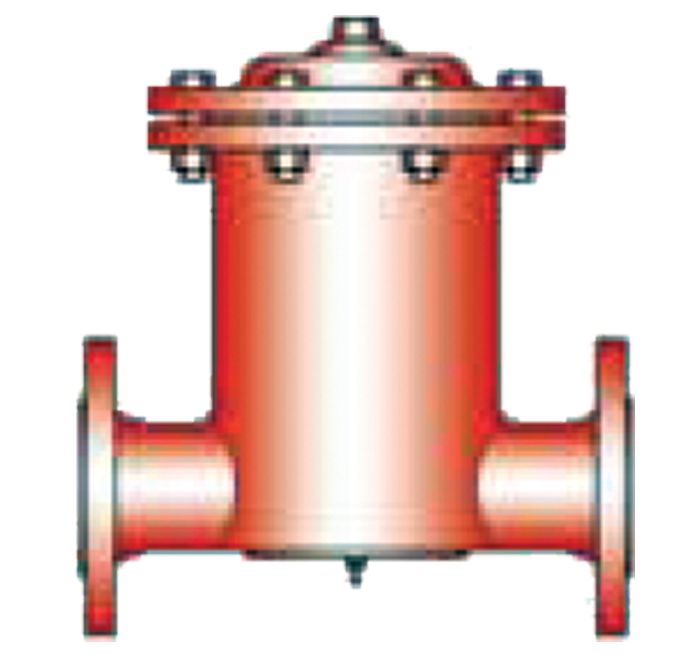

In-Line Flamearrester

Nominal Size: 10 to 1000 mm (1/4” to 40”)

VALVES

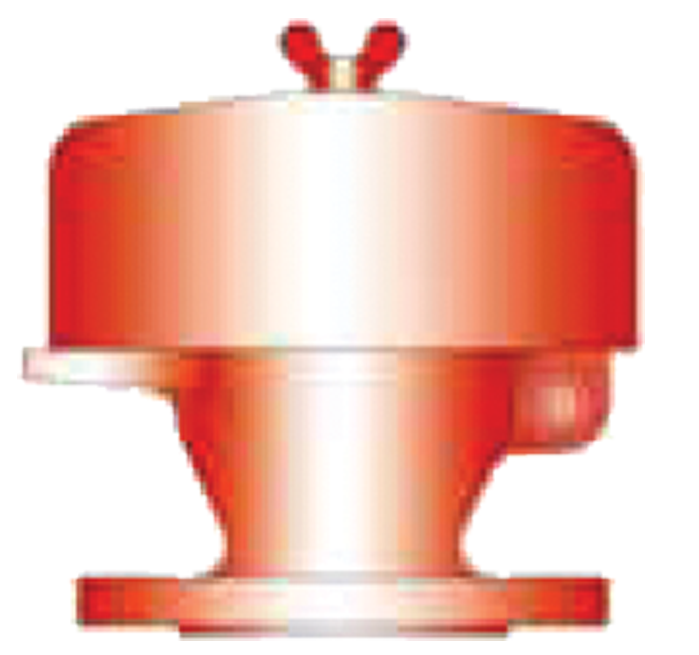

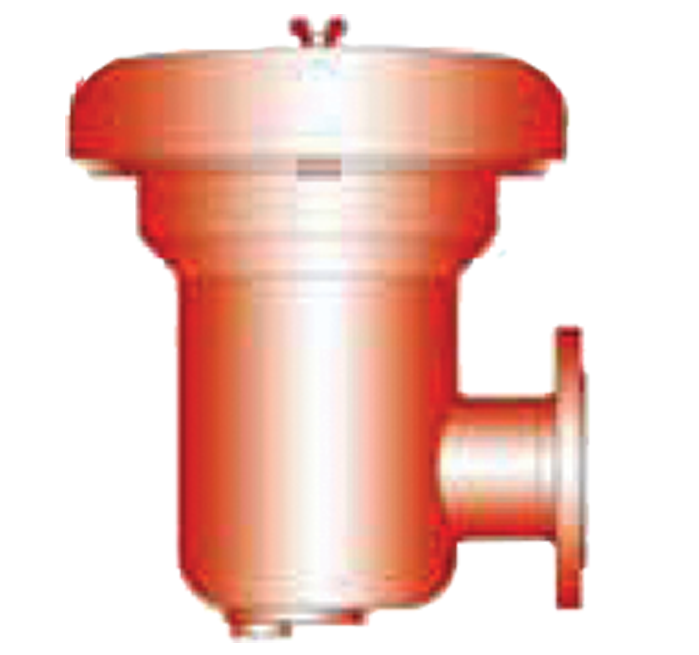

End-of-Line, Pressure & Vacuum Relief Valve

PSI: 2 – 200 mbar Nominal Size: 50 to 700 mm (2” to 28”)

In-Line, Pressure & Vacuum Relief Valve

PSI: 2 – 500 mbar Nominal Size: 25 to 300 mm (1” to 12”)

End-of-Line, Pressure & Vacuum Relief Valve w/ Flamearrester

PSI: 2 – 200 mbar Nominal Size: 50 to 300 mm (2” to 12”)

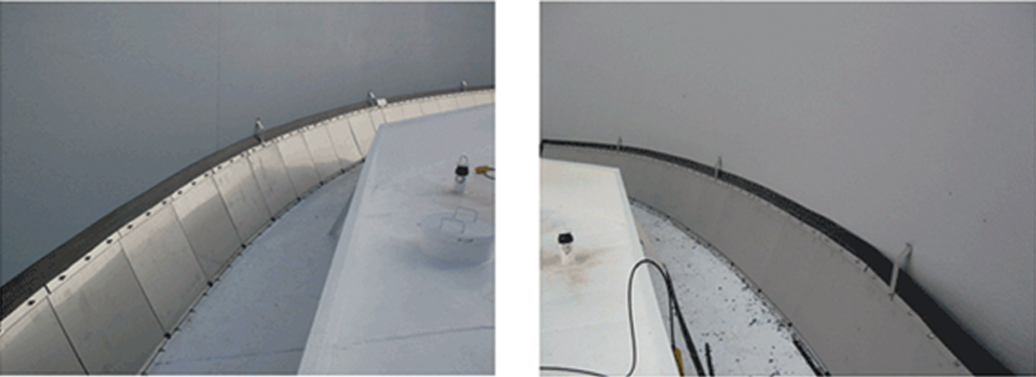

Internal Floating Roof

Many companies in petroleum, petrochemical and tank terminal throughout the world have turned to Korea Float’s internal floating roof for its superior design and efficiency. Its long-life cycle, excellent emission control and no maintenance cost are what it is known for worldwide. Korea Float’s design and manufacturing method meets API standards and specified national codes and regulations worldwide.

Advantage of K-float Internal Floating Roof

Meeting API 650 Appendix H Standard API MPMS Chapter 19.2 (Evaporative Loss)

- – Highly efficient vapor loss prevention design

- – Excellent quality Seal Material

- – Superior chemical resistance (100% Aromatic Protection)

- – Wide range of storage application

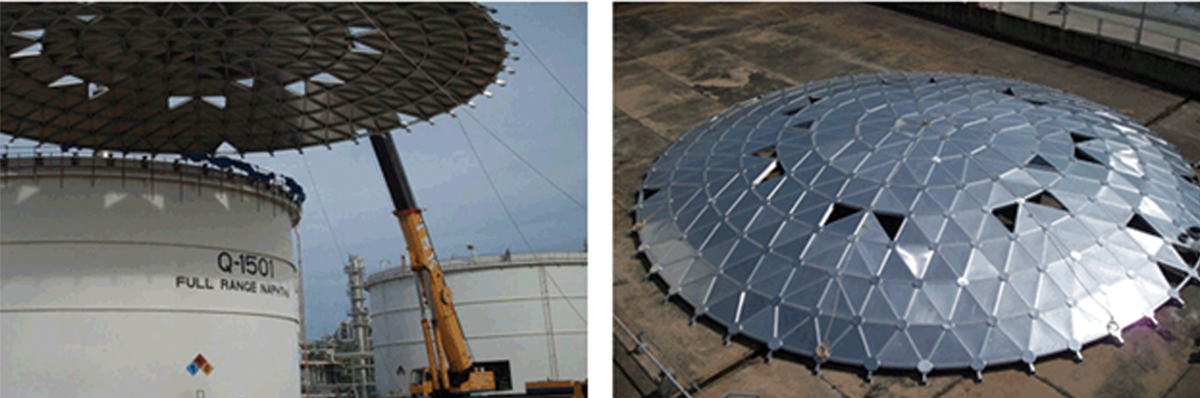

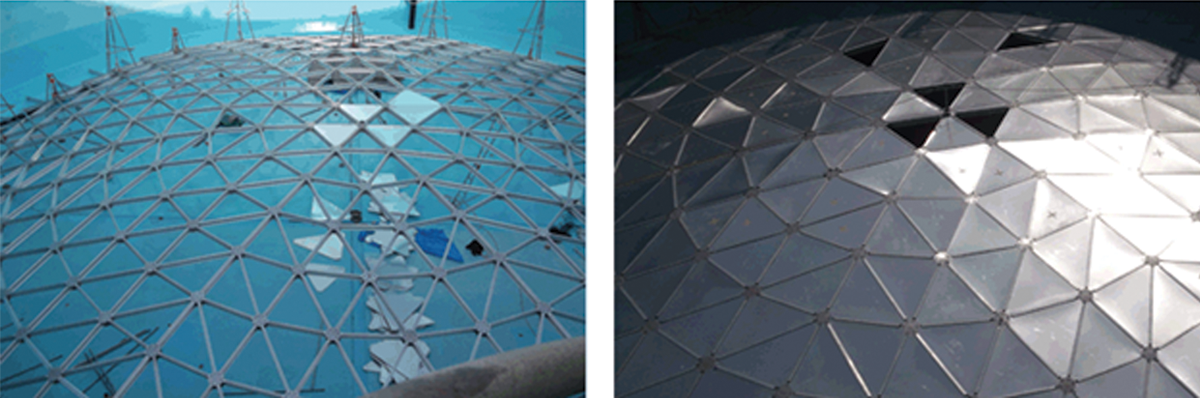

Aluminum Dome Cover

Korea Float’s AL. Dome cover provides environmental efficiency, protects stored products and reduces maintenance costs. Its reputation is built on its economic budget, light weight, and simple installation.

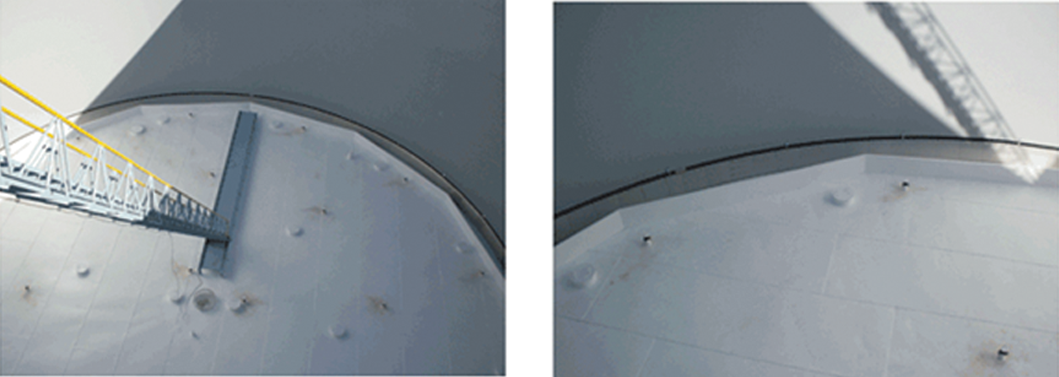

External Floating Roof

Korea Float’s External Floating Roof Seal is designed to comply with the requirement of API 630, Appendix C and environmental regulations worldwide. The space between the outer periphery of the roof and the tank shell is sealed by a flexible device that provides close contact on the shell surfaces.

Advantages of K-float External Floating roof

Meeting API 650 Appendix C Standard

- – Superior sealing capability with vapor

- – Tight and weather protection

- – Wide range of storage applications

- – Superior chemical resistance (100% Aromatic Protection)

- – Excellent resiliency, Easy to install

Plate Heat Exchanger

W - Rotary Lobe Pump

Laboratory Homogenizers

Cavitator - Controlled Cavitation Mixer

Centrifugal Pump - W + Series

Rannie and Gaulin Series

Butterfly Valves

D4 /DA4 Series - Double Seat Mixproof Valves