CST Storage is the largest provider of Factory Coated Bolted Storage Tanks for dry and liquid storage applications in municipal, industrial and agricultural markets.

CST Storage offers the only complete product line of advanced tank coatings-Vitrium glass-fused-to steel under the brand names Aquastore®, Harvestore® and Slurrystore® and OptiBond epoxy coating system Columbian TecTank® (CTT).

CST Storage provides custom designed aluminum structures and covers for industrial, commercial, recreational, transportation and other applications.

CST Storage is the worldwide leader in designing, manufacturing and onstructuring custom aluminum covers, domes and roofs.

Epoxy Coated

HydroTec tanks deliver the highest quality at the lowest cost per gallon without skimping on tank value and durability. While the PeroTec of CST is the only certified and monogrammed API-12B tank manufacturer in the world. PetroTec tanks are custom designed to meet the rigorous conditions associated with complex and volatile substances like petroleum.

HydroTech Standard Design

AWWA D103-09. ASCE-7. ANSI, AISC, API, IBC, ISO 28765, NFPA Standard 22, NSF

Tank Designs

Flat Panel Bolted

- – Leading design for bolted steel tanks around the world

- – Manufactured, erected and in operation up to three times faster than field welded or concrete applications

- – Equipped to handle large volumes up to 6,000,000 gallons (22,712,470L) and beyond

Chime Panel Bolted

- – Economical

- – Features factory formed flanges at horizontal seams for added structural strength

- – Special gaskets and sealants create leak-proof joints

- – CST has the only API-12B monogrammed chime panel bolted tank design on the market

Glass Fused To Steel

Aquastore tanks are the premium choice for storage in the municipal and industrial water, wastewater and industrial liquid markets. Proven in the field for more than 30 years, no other tank lasts longer or has greater lifetime value than an Aquastore tank. An Aquastore is not painted so it NEVER NEEDS RE-PAINTING and requires minimal maintenance over its life cycle. It also allows easy expansion in the future.

Aquastore Standard Design

ANSI/AWWA D103, ASCE-7, AISC, IBC, ISO 28765, NBCC, FM 4020/4021, NFPA Standard 22, NSF, British

Standard 7543:2003, EN1528

Tank Designs

Flat Panel Bolted

- – Leading design for bolted steel tanks around the world

- – Manufactured, erected and in operation up to three times faster than field welded or concrete applications

- – Designed to handle large volumes up to 6,000,000 gallons and beyond

Galvanized Tank

Storage tanks manufactured from galvanized steel offer many benefits over other steel corrosion protection systems. Unlike other protective coatings that rely solely on steel panel preparation to obtain adequate adhesion, galvanizing produces a coating that is bonded metallurgically to the steel.

-

- – Economical solution

- – Provides a tough and abrasion resistant coating

- – Self healing and long lasting

Design

- – Cylindrical Galvanized tanks are constructed from sheets that are manufactured from mill galvanized steel

- – in accordance with the customer’s specifications including ASTM, ASME or BS EN 10204 or from steel in

- – accordance with ASME, ASTM or BS EN 10025 that is subsequently hot dipped galvanized to ASTM,

ASME or BS EN 1461:1999 standards.

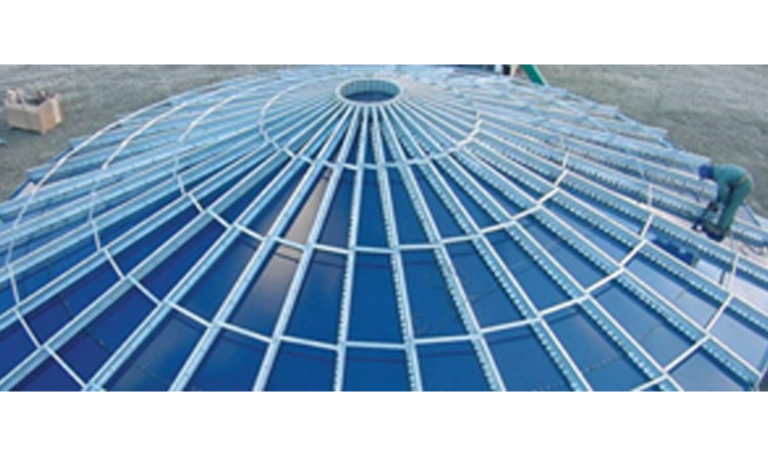

Aluminum Domes

Overview

Covers architectural domes can shape a building from the ground up. A versatile clear-span structure, CST Covers (CST) architectural domes feature a framing system of wide-flange extrusions skinned with triangular or rectilinear panels.

Fabricated from lightweight, 100% recyclable and corrosion resistant aluminum components, CST architectural domes ideally blend form and function to provide unmatched building envelope shape and geometric form options.

Corrosion Resistance

Aluminum is inherently corrosion resistant compared to other materials. It will last the lifetime of the structure and will not need to be painted or repainted for protection from the elements.

Low Lifetime Maintenance Cost

With no need to maintain a protective finish to prevent corrosion over time, there are little-to-no maintenance costs associated with an aluminum dome.

Clear-Span Capability

Aluminum’s lightweight characteristics allow for larger clear-span cover capability than structures utilizing steel, concrete and other materials.

Fast & Low-Cost Construction

Creative design and lightweight components provide for installation in 1/3 the time it takes to install other cover systems. Less time, labor and equipment needs combine for a low total cost of installation.

Design Flexibility

Aluminum’s excellent strength-to-weight ratios and creative component designs yield covers and structures that cannot be achieved with other materials.

The dome’s superior structural design gives it many advantages. Using proprietary variations of geodesic geometry, our domes are noted for their ability to meet exacting live load requirements by providing greater stiffness and strength, pound-for-pound, than any other dome geometry system.

CST Covers domes have been designed for snow loads of up to 165 pounds per square foot and wind loads of up to 150 mph. Our unique panel design is specifically engineered to support loads of up to 500 pounds on any one square foot. We have the ability to design domes up to 1000 feet in diameter.

Dome Applications

- Potable Water

- Petroleum

- Wastewater

- Bulk storage

- Architectural Structures

Flat Covers

CST Covers provides custom cover designs that are easily installed and removed as needed. No matter what the size or shape of your water or wastewater basin CST Covers will provide right aluminum flat cover solution. Aluminum flat covers can be self-supported or supported with trusses and other structural members

Overview

Extruded Flat Panel Covers

Our extruded panel cover design is available in clear spans up to 18 feet (4.57m) and custom designed to meet your project’s specific functional and design loading requirements. All-aluminum design constructed of 6061-T6 and 6063-T6 aluminum structural members and 6063-T6 sheets ensures quality, durability, and longevity.

Formed Flat Panel Covers

Our formed panel cover design is available in clear spans up to 30 feet (9.14m) and custom designed to meet your project’s specific functional and design loading requirements. By using quality 5052-H32 aluminum panels and 6061-T6 structural members along with the proper sealant and gaskets, CST Covers ensures ultra-low maintenance for the life

of the cover.

Air Tight — Great for odor control.

Corrosion Resistant — All-aluminum structure is corrosion resistant, maximizing product lifecycle.

Structurally Safe — Constructed with a slip resistant surface for personnel safety.

Low Profile Design — Less air volume to be contained and treated.

Removable Panels — Interlocking male-to-female joints between panels allow for easy removal of any or all panels with no special tools needed.

Lightweight — No heavy machinery necessary to remove panels.

Ease of Installation — Easily constructed of lightweight material.

Truss or Beam Supported Flat Covers — Available for larger spans.

Other Roof and Covers

STEEL ROOFS

Sloped Steel Roofs

A very common and economical roof design when no design pressure is required and under standard roof loads. It can be epoxy coated, stainless steel or other alloys as specified. Large diameters can use multiple column supports.

Externally Supported Roofs (ESR)

The most common roof design in the industry with a smooth internal roof surface and no rafters. Used when moderate to high pressure or vacuum design limits are anticipated. It is also preferred when there are heavy load conditions expected from mixers and/or other ancillary equipment is installed in the cover.

Knuckle Roofs

Knuckle roofs are an option for smaller diameter storage tanks. They are best suited for lighter pressure and vacuum applications with minimal load bearing requirements. They are fabricated with glass-fused- to-steel coating or stainless steel to provide excellent gas zone longevity

Membrane Covers

Single Membrane Cover

Designed to operate in applications with low to moderate gas pressures where there is not a design requirement for a fixed steel or aluminum cover. Multiple layers and optional center support structures are utilized depending on design considerations.

Membrane Gas Holders:

CST can provide membrane gas holder that are commonly used in conjunction with other storage vessels to store and regulate gas form the process and send it to the generating set or flare device